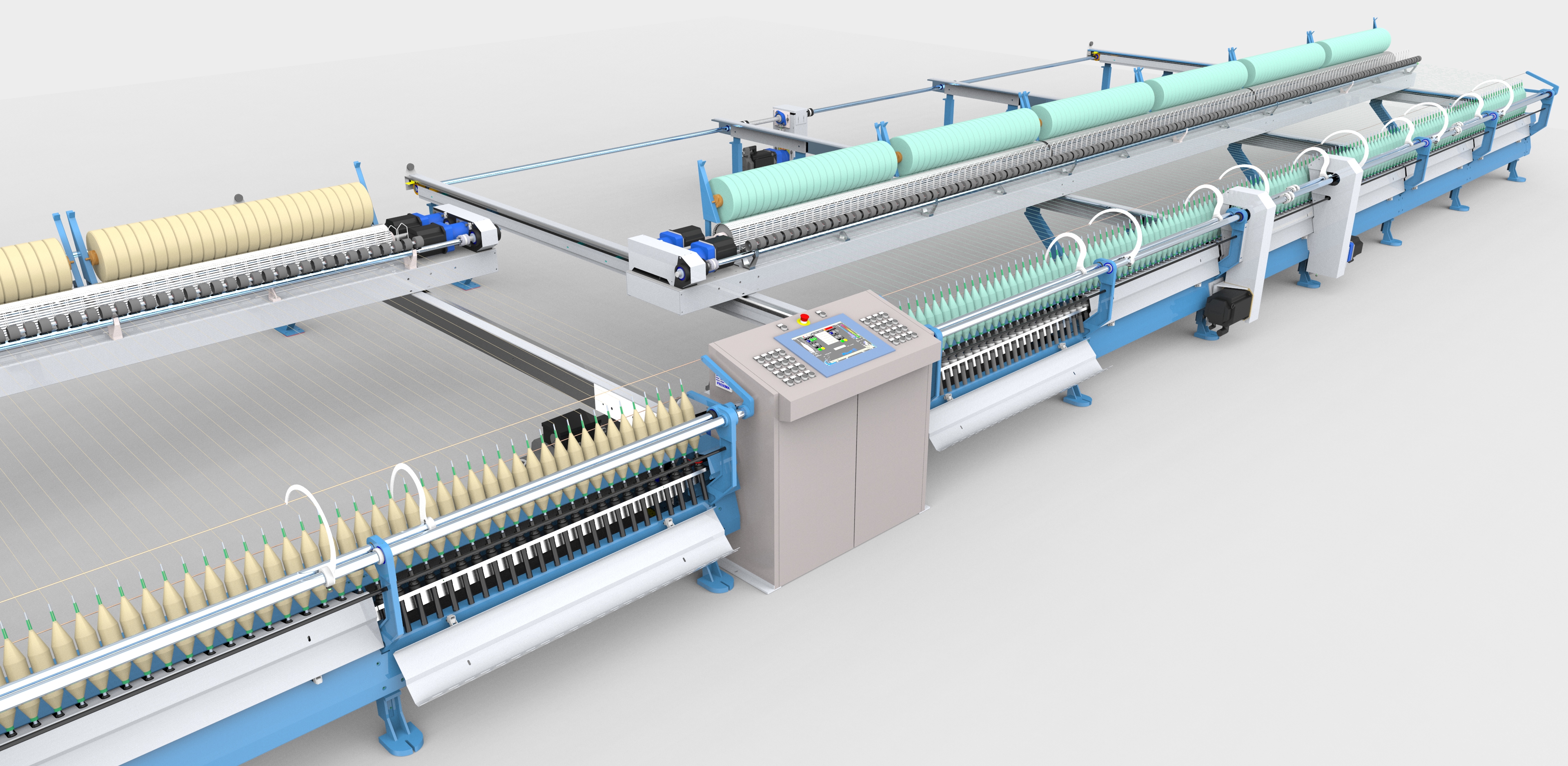

- ● It is composed by two completely independent sections, this improvement brings more flexibility, more production and reduction of downtime.

- ● The new installed electronics and the new software allow an important energy saving. In order to produce the same product quantity this machine has the lowest energy consumption with 290Wh and a reactive power (≈o) with Cos φ = 1 per kg of pure cashmere yarn 15000Nm count with 300 twists / meter.

- ● Data of each processed lot are stored and can be re-called and processed again in the future.

- ● Faults are minimal (close to zero).

- ● It has a low environmental impact, does not use compressed air and does not produce carbon dust because it uses exclusively brushless motors.

- ● It can be integrated with various automation systems.

The textile industry, in order to guarantee a new growth boost, is moving towards production models with energy-efficient processes with reduced environmental impact. The Italian textile machinery industry works to provide technological solutions that put at the center of the production process the reduction of energy, water and chemicals for a more responsible and consumption-friendly production cycle that respects the environment. The commitment of Italian textile machinery manufacturers lies in the search for solutions that respond to the canons of sustainability. Commitment that brings to ecologically efficient and effective technological responses, with significant benefits for those who use these technologies also in terms of reducing production costs.