Custom design

Our long experience and knowledge allows us to customize our machinery to many different requests and to suggest to the customer the most appropriate solutions for the specific production he needs. thanks to a customized design and a customization service.

Assistance

Thanks to remote assistance, we solve breakdowns or machine downtime in real time by connecting directly to the machine. In this way the interventions on the fault is immediate and reduces the loss of time.

Selfacting mules

-

forwardPROXIMA B7 DD

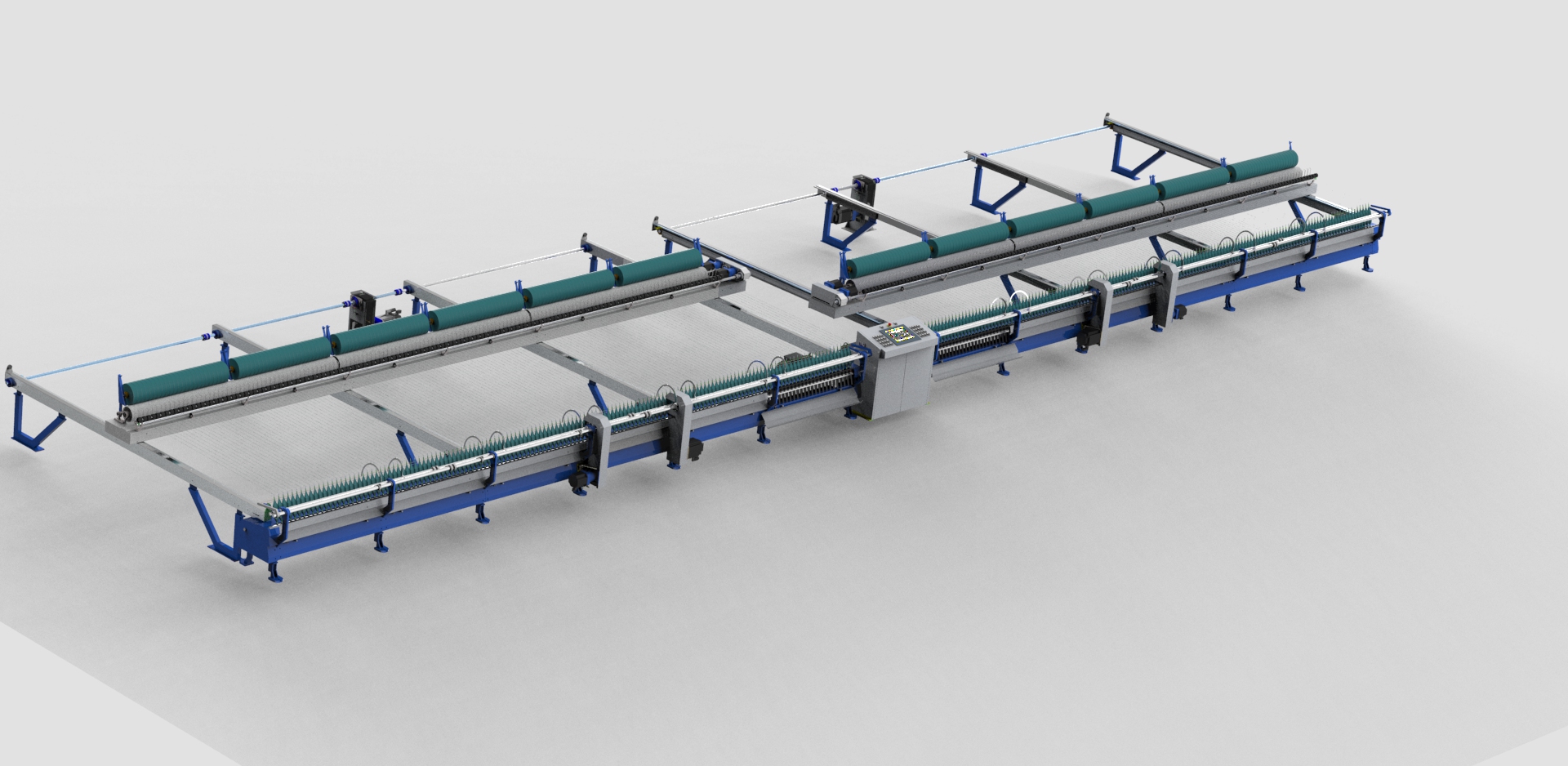

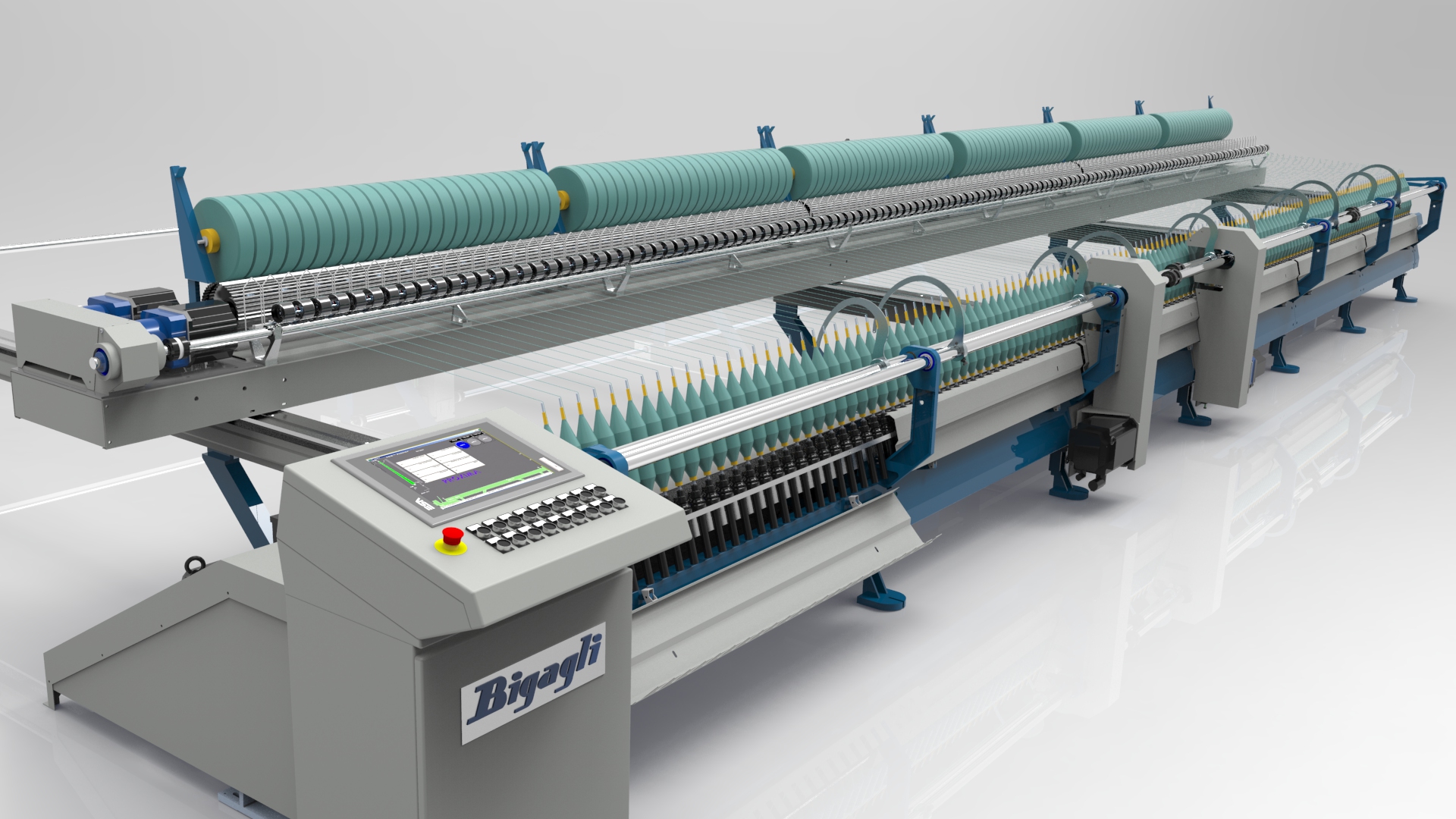

The new selfacting mule mod. “Proxima B7DD” is composed by two sections completely independent.

Advantages:

- ● Increased production - the possibility of operating on a single section reduces the total time of machine stop, relevant to cop replacement, bobbins replacement and all stops effected through the switch bar. A section can be stopped and at the same time the other section can work normally.

- ● Increased quality and lower cost - mechanical, electronic and software modifications have allowed to produce very fine and delicate yarns like cashmere 100% count 46.000. Moreover it grants a significant energetic costs saving and a reduced enviromental impact as demonstrated by Green Label certification.

- ● Increased flexibility - the independent sections allow to work two different articles at the same time as if you had two distinct selfacting mules. The greatest advantages are evident in the management of small lots and lot ends.

The control cabinet is placed in the central part of the selfacting mule. It contains the push buttons of both sections and the PC with operator interface.

Movement of the machine is granted by 12 Siemens brushless motors controlled by the Siemens controller " Siemens Simotion ".

Interaction between operator and machine is possible through an interface realised with guided menu which can enable right side and left side pushing on the touch-screen. Menu includes production managing, alarms and parameters modification history. The machine can be controlled through intranet and internet, as per Industry 4.0 requests.

-

forwardPROXIMA B7 DF

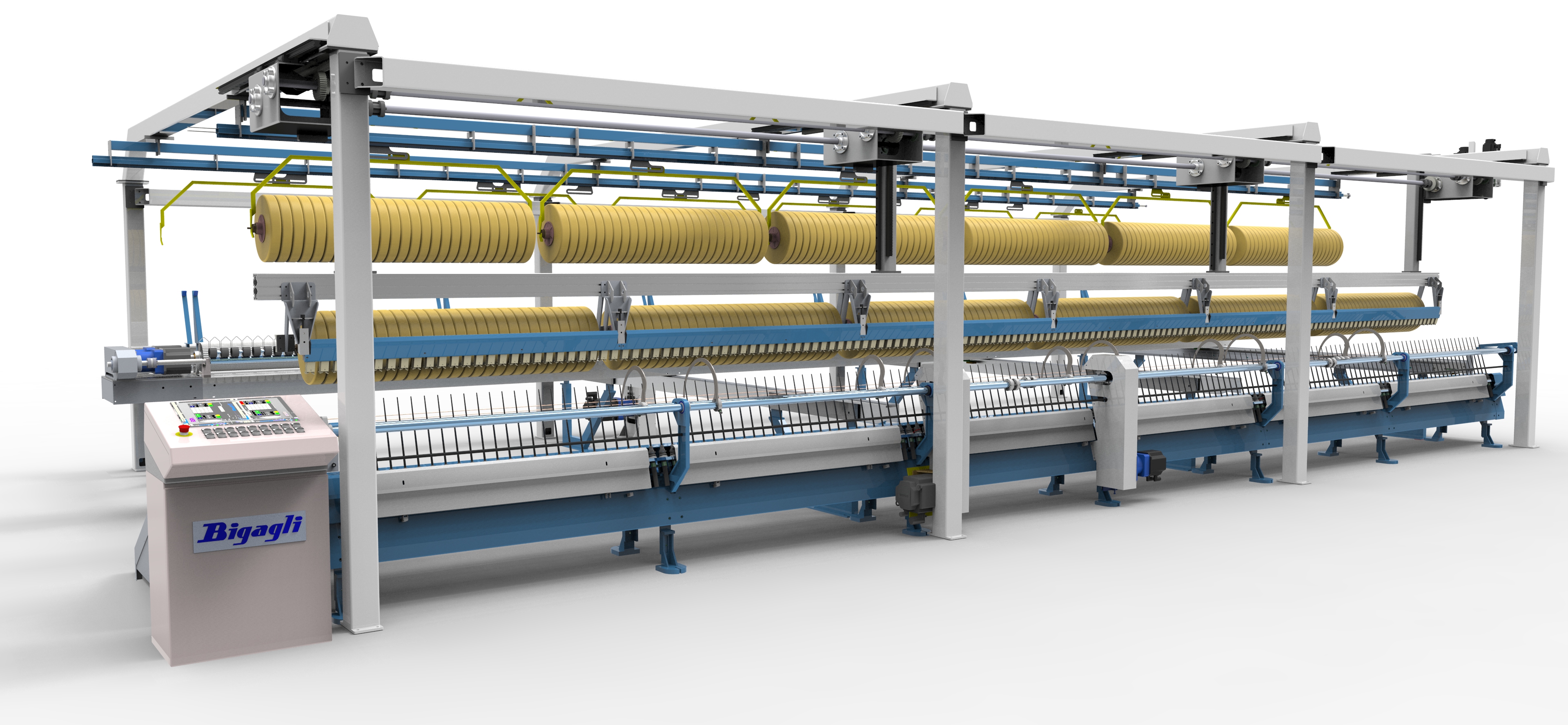

Spinning mule model " Proxima B7DF " is composed of two sections completely independent of each other like the B7DD but in addition the two sections, each with its own console, are mechanically separated so as to allow positioning, for example one of facing each other, ideal for small environments.

-

forwardAutomation

All our machines can be integrated with automatic devices such as automatic doffing and bobbins replacement.

Services

-

forwardReconditioning and update of second hand machines

Old generation machines can be reconditioned and updated to modern machines with new electronics, motorization and revision of the mechanical part. Thanks to reconditioned works you can obtain quality and performance of current machines at low cost.

-

forwardSpare parts for Bigagli machines

Feel free to contact us for a quotate within 24 hours with costs and delivery times. We provide a fast and efficient spare parts service for both Italy and abroad.